Hyundai Moves Atlas to the Production Line: A High-Stakes Bet on Humanoid Labor

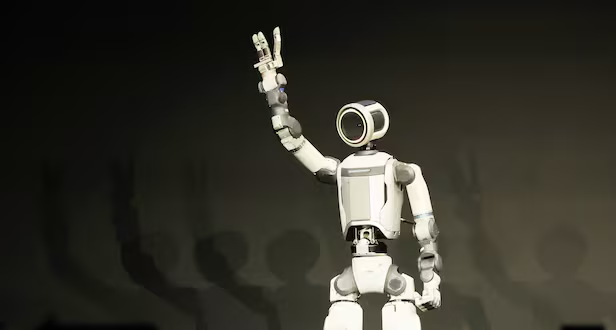

LAS VEGAS — There was a distinct lack of the familiar hiss and whine of hydraulics when the new Atlas stepped onto the Mandalay Bay stage this morning. Instead, a low-frequency electric hum preceded the robot as it performed a 180-degree torso twist—a movement that would be biologically impossible for a human, yet looked unnervingly fluid for a machine. At CES 2026, Hyundai Motor Group and Boston Dynamics made it clear: the days of viral parkour videos are behind them. This is the debut of a tool designed for the grueling monotony of the automotive assembly line.

This all-electric iteration of Atlas is the centerpiece of Hyundai’s "Software-Defined Factory" initiative. While the prototype phase teased us with backflips, this production-ready version is built for the "boring" work: parts sequencing, logistics, and eventually, complex component assembly. The mandate is aggressive, with the first units scheduled to transition from training environments to active shop floors within the next 24 months.

Precision Over Acrobatics: The Hardware Shift

The next-generation Atlas has been re-engineered for "dextrous manipulation," a move away from the gross motor skills of its predecessors. It features 56 degrees of freedom, powered by fully rotational joints that allow the robot to operate in cramped factory footprints without the need for the wide turning radiuses required by human workers or traditional AGVs.

The most critical hardware departure is the hand assembly. Unlike Tesla’s Optimus, which leans heavily into a vision-only philosophy for object manipulation, Hyundai has equipped Atlas with human-scale hands featuring integrated tactile sensing. During the demo, the robot didn't just "see" a glass component; it "felt" the pressure required to grip it without fracturing it.

However, this mechanical complexity comes with a catch. Each of those 56 degrees of freedom represents a potential point of mechanical failure. In a high-uptime environment like an auto plant, the cost of maintaining a fleet of such high-precision machines remains a significant question mark. Hyundai has yet to disclose the mean time between failures (MTBF) or the per-unit price point, both of which will determine if this is a viable solution or an expensive experiment.

The Roadmap to 30,000 Units

Hyundai is bypassing the usual cautious pilot phase in favor of an accelerated "Value Network" integration. The company confirmed that the entire 2026 production run has already been spoken for, allocated internally to Hyundai Motor Group and its strategic AI partners.

The rollout follows a strict hierarchy:

-

2026: Launch of the Hyundai Robotics Metaplant Application Center (RMAC). This facility will serve as the primary laboratory for training and pilot programs, refining how Atlas interacts with heavy industrial equipment.

-

2027–2028: Full-scale deployment at the HMGMA Metaplant in Georgia and other global hubs. The goal is to have 30,000 units in operation by the end of 2028.

-

2030: Evolution from simple logistics and "pick-and-place" tasks to high-precision assembly roles.

By using its own factories as the primary testing ground, Hyundai is following a validation path similar to Tesla’s. However, the sheer scale of the 30,000-unit target by 2028 will test the limits of current battery density and the global supply chain for high-torque electric actuators.

Physical AI and the Software-Defined Factory

The transition from hydraulic to electric power isn't just about removing messy fluids; it’s about data. Electric actuators provide instantaneous telemetry, allowing every micro-movement to be logged, analyzed, and optimized via over-the-air updates. This is the foundation of "Physical AI," a field Hyundai is aggressively pursuing through a partnership with Google DeepMind.

By utilizing advanced foundation models, Atlas can learn tasks in simulation before attempting them on the floor of the Hyundai Motor Group Metaplant America (HMGMA). Chairman Chung Euisun has described this as a cultural pivot, moving the company away from being a mere vehicle manufacturer and toward becoming a robotics-first organization.

The challenge remains integration. While Atlas can learn to move a part in a simulated environment, the chaos of a live factory—varying light levels, human interference, and unpredictable hardware wear—is a different beast entirely. Hyundai is betting that its "Mobile Living Computer" approach will turn the factory itself into an intelligent ecosystem, but the success of Atlas will ultimately be measured not by its intelligence, but by its reliability on the graveyard shift.